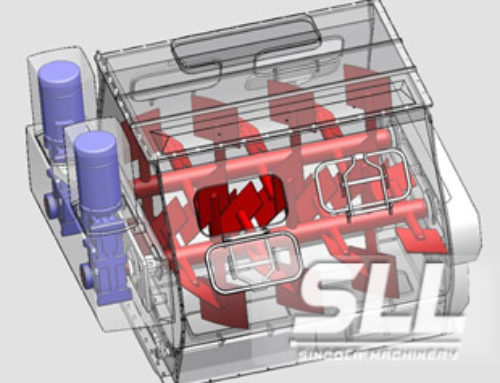

Single shaft coulter mixer

Product Details:

| Place of Origin: | Zhengzhou,China |

|---|---|

| Brand Name: | SINCOLA |

| Certification: | ISO,CE,SGS |

| Model Number: | SLD-8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1sets |

|---|---|

| Price: | USD19000-31000 |

| Packaging Details: | Nude Package in 20ft container |

| Delivery Time: | 10days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 4sets 30day |

| Model | SDM1-8 | Output: | 8-90tph |

|---|---|---|---|

| Power | 11-75kw | Height: | 1.7m |

PRODUCTS LIST

|

Model |

Output(t/h) |

power(kw) |

Overall dimensions(mm) |

||

|

L |

W |

H |

|||

|

SLD-1 |

8-10 |

11 |

2700 |

1584 |

1756 |

|

SLD-2 |

15-20 |

18.5 |

3300 |

1584 |

1756 |

|

SLD-4 |

35-40 |

55 |

4800 |

1700 |

2200 |

|

SLD-6 |

55-60 |

75 |

5168 |

2100 |

2398 |

|

SLD-8 |

80-90 |

75 |

5340 |

2383 |

2608 |

- The latest concept of plough blade type mixing mechanism of the use of core technology, coupled with the high speed rotating cutter of the discrete type mixer, mixing speed, depending on the product formula, host mixing time of 90-180/s, the powder is more strongly attached to the aggregate.

- mixing console a mixture of high precision, good workability and evenness, of various materials each batch product homogeneity is good, do not produce segregation when mixed, stirred the mixing ratio of up to 1, 000, to maximize meet the construction requirements.

- unique single door discharging device. When discharging without dead zone, no residue, no leakage material, discharge time is short. For color mortar, when replacement product formula simply cleaning or not.

- equipped with dynamic artificial sampling mouth, convenient user testing samples, and according to the product’s inspection status to adjust the mixing time of the host, to meet the production requirements.

- mixing barrel and mixing blade USES is imported alloy wear-resistant plate, high-speed fly knife.

Colter mixing machinery for mixing sand , by the driving wheel reducer shaft drives the coulter group movement, on the one hand, the material along the radial circumferential turbulent cylinder circumference of a circle, at the same time the material along the normal direction on both sides of the coulter throw, on the other hand thrown material by fly knife group, stirred by high-speed rotating knife throwing shearing and strong scatter, material under the compound action of coulter and throwing knives, constantly change, diffusion, solid – solid block (powder and powder), solid, slurry (powder and glue slurry) material or material can also be mixed density differences.

High mixing capacity biaxial agravic mixing machine is make full use of the mixed convection principle, it is using up movement of materials inside the mixer flow layer formation, produce instant weightlessness, to the best state of mixed effect. In the field of the flow layer, the material in A circumferential speed to overcome the centrifugal force, under the action of A specific Angle of blade by A to B, with moving blade within the time to send it to C, have the same specific Angle of the blade and then send it to D, then by D back to A; And, in particular material overlapping leaves, under the action of axial movement, is implemented in the full scope of mixed, random optimal motion state formation.