Cement mortar mixer machine

Product Details:

| Place of Origin: | Zhengzhou,China |

|---|---|

| Brand Name: | SINCOLA |

| Certification: | ISO,CE,SGS |

| Model Number: | SLHJ300-2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1sets |

|---|---|

| Price: | USD1350-5380 |

| Packaging Details: | Nude Package in 20ft container |

| Delivery Time: | 3days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20sets 30day |

| Model | SLHJ-300-2000 | Output: | 300-2000Kg/batch |

|---|---|---|---|

| Min/batch | 3-6 | Power | 2.2-11kw |

PRODUCTS LIST

| Model | SLHJ-300 | SLHJ-500 | SLHJ-1000 | SLHJ-1000 | SLHJ-2000 |

| Kg/Output | 300 | 500 | 1000 | 1000 | 1500 |

| Homogeneity cv% | 95% | 95% | 95% | 95% | 95% |

| Min/batch | 3-6 | 3-6 | 3-6 | 3-6 | 3-6 |

| Power kw | 2.2 | 5.5 | 7.5 | 11 | 11 |

| Lift kw | 2.2 | 2.2 | 2.2 | 2.2 | 4 |

1.Suitable for producing the construction masonry mortar , plastering mortar, the caking mortar, the anti-crack mortar, the self-leveling floor mortar, the runway, the patching mortar, the highway-patching mortar, the ceramic tilepointing medicinal preparation, the sealing medicinal preparation, the outer wall flexible putty, the inner wall decoration putty and mixture of many mixes with many materials .

2.Long life: the easy injured part of the equipment adopts components of high strength wearresistant steel which guarantee its useful life.

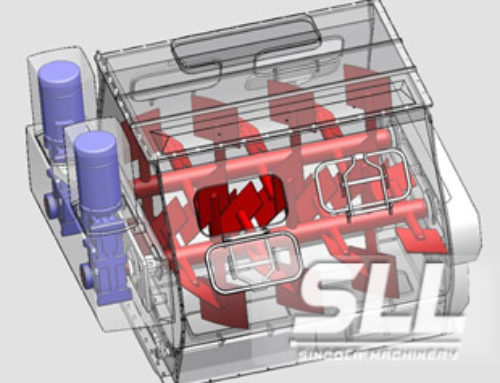

3.Good dispersion: the equipment totally solves the problems like low uniformity caused by the proportional weight of material and dead space. It adopts the structure stirred by three spirals, dispersing all kinds of short fiber.

There are two types of mixer for dry mortar: Multi Spiral Ribbon Mixer.

premixed dry mortar twin screw blender manufacturer is characterized by high mixing precision, and wide application to food, chemical industries, and building lines. The major sections of a mixer are barrel, ribbon agitators, feeding ports, discharging port and driven unit.

Double ribbon mixer drive the material from two ends to centre through the help of the outer ribbon, while the inner ribbon push the material from centre to two ends, thus, material achieve a high mixing effect at short time!

1. widely used in the mixed powder, granular, flake, block, such as materials in the feed, food, chemical, fertilizer , consttruction and other industries.

2. Specially -designed discharger has big door-opening angle an quick discharging with less residue.

3. Sealing system has good tightness, ensuring no products leakage.

4.Users can choose carbon steels and stainless steels.

5. can be equipped with heating or cooling jacket if temperature control is required. Besides, all of our powder mixer can tolerate about 10% liquid additives! We will add spraying or atomizing unit inside the tank!