Project Description

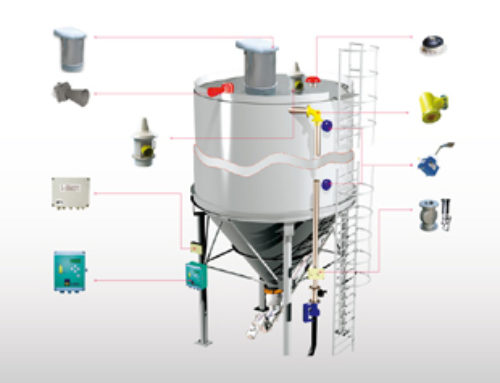

Cement silo Part

Product Details:

| Place of Origin: | Zhengzhou,China |

|---|---|

| Brand Name: | sincola |

| Certification: | ISO,CE,SGS |

| Model Number: | SC-part |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1sets |

|---|---|

| Price: | USD3-635 |

| Packaging Details: | Carton packaging, wooden packaging ,Nude Package in 40ft container |

| Delivery Time: | 1days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100sets 30day |

| Model | SDM50 | Output: | 50tph |

|---|---|---|---|

| Area: | 60~500㎡ | Height: | 10-30m |

PRODUCTS LIST

Dust collector cement silo

specific parameters:

The filter area: 24 square meters

Cartridge number: 14

The exhaust air rate: 1500 m3 / h

Filtration efficiency: > 99.9%

Cleaning method: intermittent vibration cleaning

Power vibration motor: 500 watts (380 V / 50 Hz)

The structure of the form: cylindrical

Diameter: 800 mm

Total installation height: 1635 mm

Connection: clamp connection (with seal)

Shell material: carbon steel

Paint color: Yellow / Grey / red

Weight: 100kg

All models:

Level indicator

Level indicator |

1.type:copy WAM

2.Shaft length:90mm,,500mm,1000mm 3.220VAC or 24VDC 4.Blade material: stainless steel 5. Installation method: Screw |

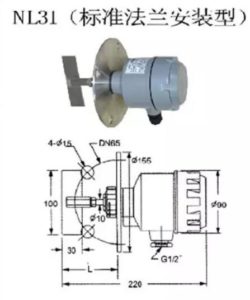

Level indicator |

1.type: screw type

2.Shaft length:90mm or customized 3.220VAC or 24VDC 4.Blade material: stainless steel5. 5.Installation method: Screw |

Level indicator |

1.type:flange type

2.Shaft length:90mm or customized 3.220VAC or 24VDC 4.Blade material: stainless steel 5.Installation method: Flange |

Level indicator |

1.type:high temperature

2.Shaft length:90mm or customized 3.220VAC or 24VDC 4.Blade material: stainless steel 5.Installation method: screw |

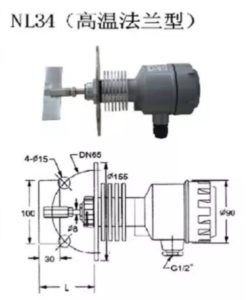

Level indicator |

1.type:high temperature

2.Shaft length:90mm or customized 3.220VAC or 24VDC 4.Blade material: stainless steel 5.Installation method: Flange |

Level indicator |

1.type:high temperature tube type

2.Shaft length:90mm or customized 3.220VAC or 24VDC 4.Blade material: stainless steel 5.Installation method: Flange |

|

|

1.type:flexible shaft

2.Shaft length:90mm-1000mm 3.220VAC or 24VDC 4.Blade material: stainless steel 5.Installation method: Flange |

High Pressure cement Safety Valves of cement silos

High pressure cement safety valves

High pressure cement safety valves VAM standard are used the discharge the high pressure in the cement silo. Those valves start to run when the pressure value reaches the pre-set pressure limit value.

Those valves are the equipments that keeps the pressure in the cement silo in desired values and prevent the cement silo filter from breaking down.

The cement is transferred from silobus to cement silo with high pressure. In case there is no cement in the silobus, only the air is transferred into the cement silo and thus there occures high pressure in the cement silo. At this moment if high pressure safety valves do not start to run , the cement silo and the cement silo filter can be damaged seriously.

Butterfly valve VAM standard switch is mainly used for the silo bins, hoppers and equipped with powdery or granular materials. It can be applied to deal with all powdery and granular materials, the use of the material itself gravity valve closure and pneumatic transport of dry materials. It may be installed below the hopper, bin, silo, screw or other type of conveyor.

Butterfly valve VAM standard switch is mainly used for the silo bins, hoppers and equipped with powdery or granular materials. It can be applied to deal with all powdery and granular materials, the use of the material itself gravity valve closure and pneumatic transport of dry materials. It may be installed below the hopper, bin, silo, screw or other type of conveyor.

Pneumatic butterfly valve with double flange cement-silo

broken arch

Arch breaker device

Arch breaker device

Silo broken arch anti-blocking system auxiliary discharge flow BAS series is a broken arch promote and maintain powder and bulk material in the silo and smooth outflow for the purpose of cost-effective solutions. Hopper broken arch anti-blocking system auxiliary discharge flow through the nozzle broke out between the material and the realization of the silo wall form a strong radial pulse airflow surface, forcing the material and the silo wall cut off, thereby reducing material between each other, the material and the coefficient of friction between the silo wall and accelerate the flow of materials.

Screw Conveyor

Cement Sand fly ash Screw conveyor is designed to provide operating convenience to our customers and is implemented in all Oriental cement screws as standart. Oriental cement screws are manufactured at Ø114, Ø165, Ø219, Ø273 ve Ø323 diameters.Semi-open type cement screws are specially designed to use in Oriental MOBILE MASTER-60 mobile concrete batching plants.